HEM® Ti:Sapphire

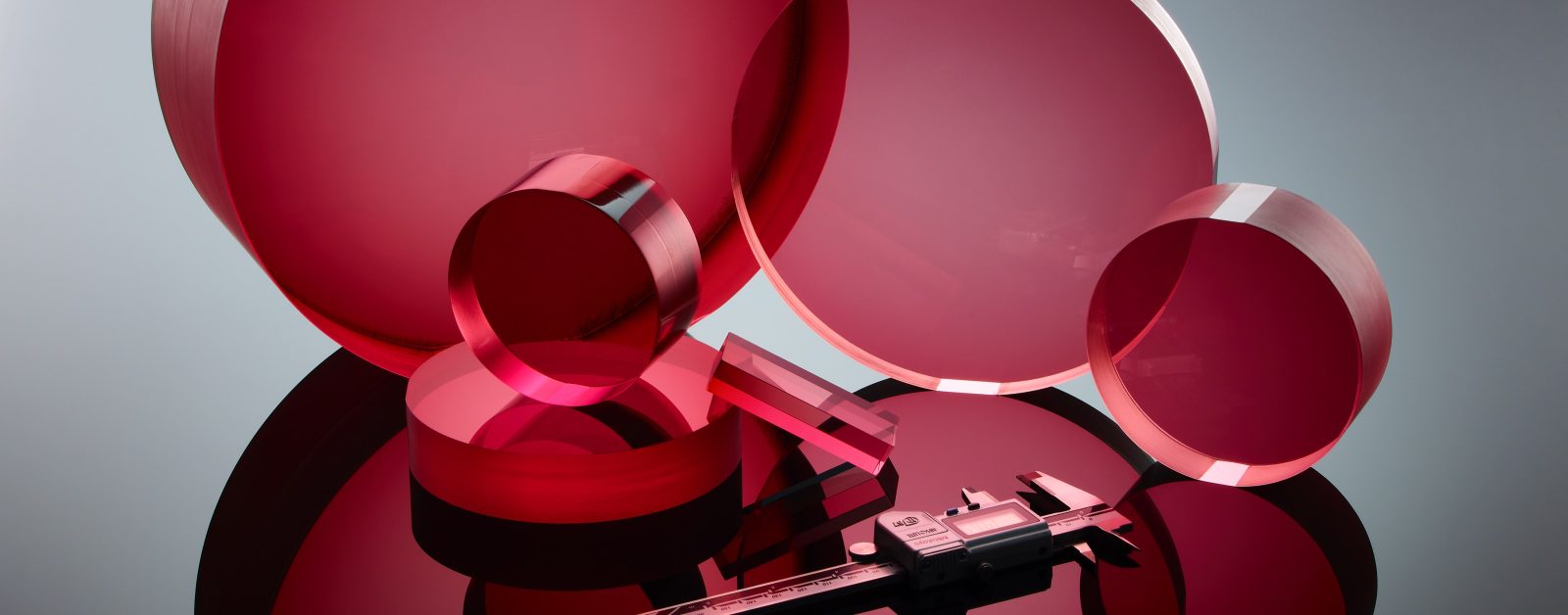

- Laser Crystals Commercially Available up to 120mmØ. Greater than 120mmØ through R&D Programs.

- Many Design Options Including Rectangles, Squares and Your Unique Designs

- Path lengths Ranging from 1mm to 75mm

- Highest Laser Damage Threshold Coatings Available

- Low Damage Polished Plano-ends, Brewster's Angle Ends

- Absorption Values From 0.5 to 8.0 /cm @ Alpha 532nm

Demanded by the world’s top ultrafast lasers utilizing Femtoseconds & multi petawatt systems.

Crystal Systems’ proprietary HEM® technology produces superior crystalline structures in crystal sizes commercially up to 120mmØ with larger sizes available through R&D programs.

We are proud to have delivered 200mmØ and 220mmØ HEM Ti:Sapphire laser optics in support of today’s leading-edge high-intensity laser facilities.

Low damage HEM Ti:Sapphire laser materials are processed with extremely tight geometries and crystal alignment. Our ultrafast laser optics have transmitted wavefront values of 1/10th or better, and FOM values up to 500. All aspects of crystal quality and optical fabrication workmanship are verified with our specialized test and measurement equipment. We provide detailed quality reporting on the laser, optical, and mechanical attributes of our HEM Ti:Sapphire laser crystals. Crystal Systems has worked with the international community of high-intensity laser experts to develop the current range of HEM Ti:Sapphire ultrafast laser optics.

Performance Characteristics

- 120mmØ

- Excellent Homogeneity

- Superior Thermal Properties

- High Figures of Merit (FOM)

- No Bulk Scatter

- High Laser Damage Threshold

- Large Sizes and Highly Doped Material Available

- Alpha Values @ 532nm of 0.5-8.0/cm

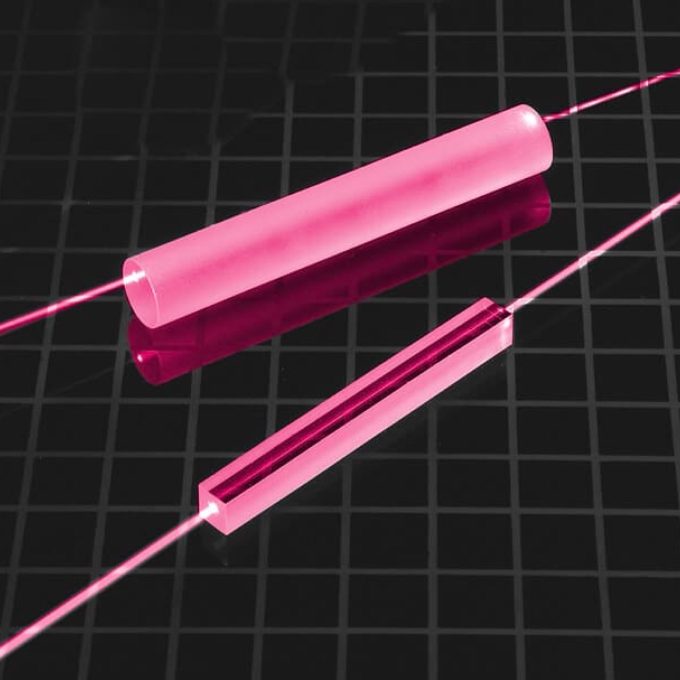

High quality laser crystals begin with our near perfect crystalline structure and the correct 3+ valence electron state.

Each HEM Ti:Sapphire laser rod guarantees the foundation for your laser platforms’ high power levels and excellent beam profiles.

Through rigorous examination processes and state-of-the-art equipment, our crystals are tested for absorption values, homogeneity, light scatter, FOM, flatness, and transmitted wave fronts.

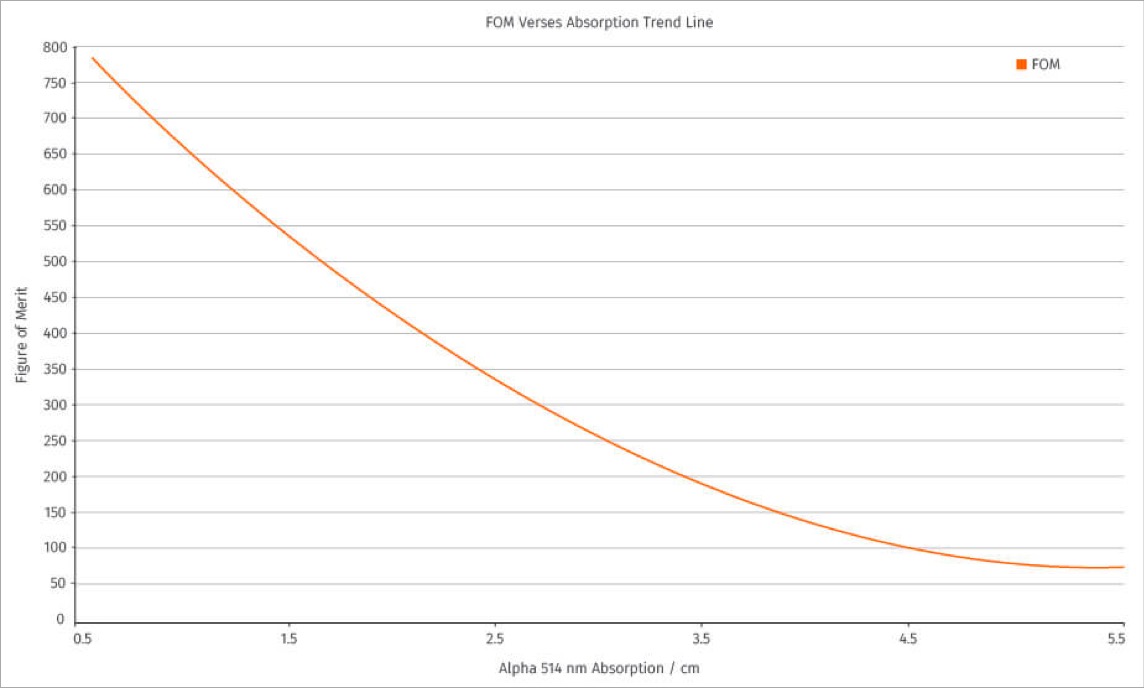

FOM (Figure Of Merit) Vs. Absorption

The HEM process has been developed to maximize absorption @ 532nm and reduce parasitic absorption at 800nm, thereby delivering the highest FOM values in the industry. Each Crystal Systems HEM Ti:Sapphire crystal is tested for actual FOM values, and these values are known to be the highest in the industry.

Tunability Range of HEM Ti:Sapphire

HEM Ti:Sapphire has a wide tunable range from 650nm to 1200nm with peak intensity at ~800 nm. The wide bandwidth of the material allows for short pulses and high repetition rates. Our Ti:Sapphire laser optics are offered in a range of titanium doping concentrations, (0.5 to 8.0 @ alpha 532nm) which allows adjustment of overall path length designs to meet your desired low power single pass absorption (LPSP).

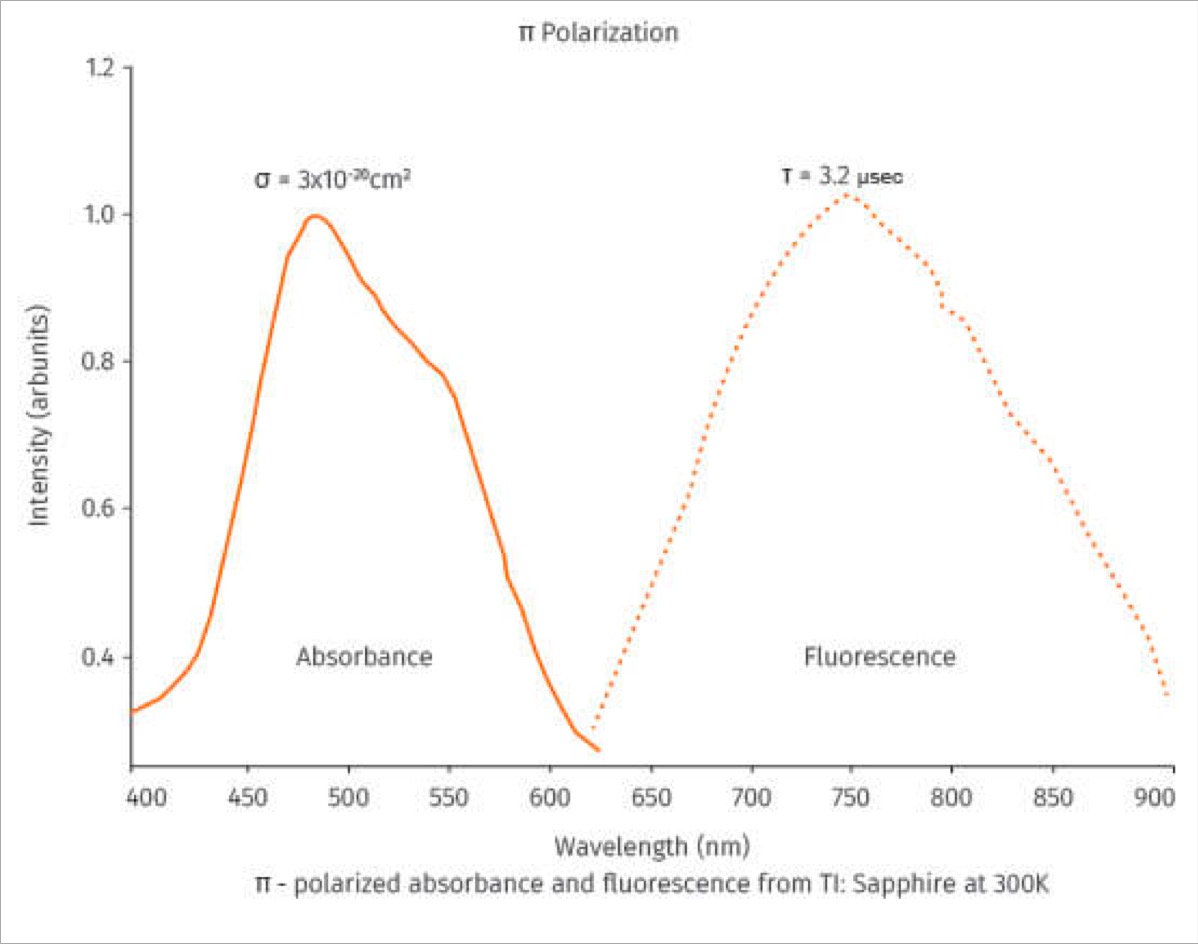

Absorption / Fluorescence

Ti:Sapphire lasers are typically operated using π-polarization. This chart shows the absorption and fluorescence bands of HEM Ti:Sapphire in π-polarization.

Brewster’s Angle Laser Crystals

Most of our smaller crystals are polished at Brewster’s angle to minimize reflection losses. Brewster’s angle is based on the index of refraction of the material. The index of refraction for Ti:Sapphire is ~1.76, resulting in ~60.4° Brewster’s angle. The accuracy of our C-axis rotation is tightly controlled to avoid laser modulation.

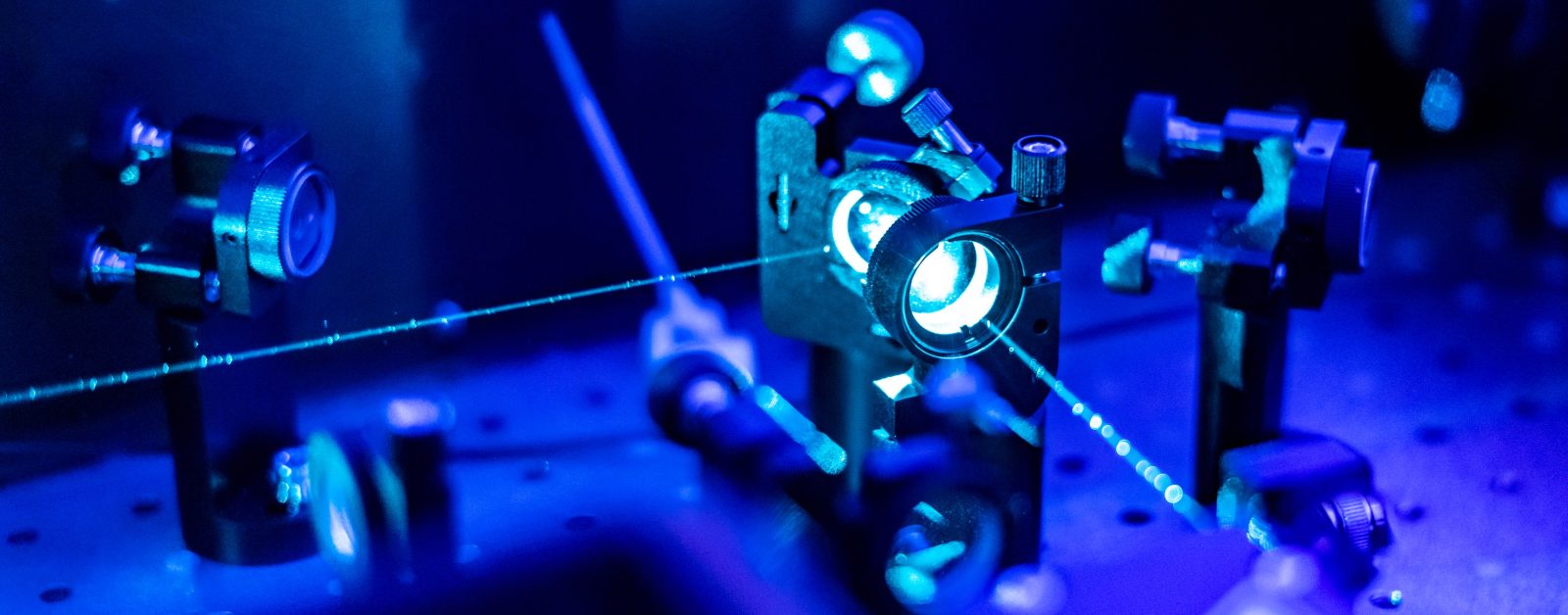

Advanced laser polishing and high damage coatings

Crystal Systems applies the most advanced polishing technologies to its high-power laser optics in order to create sub Angstrom-level roughness with low sub-surface damage. We perform testing to ensure high and repeatable laser damage threshold values.

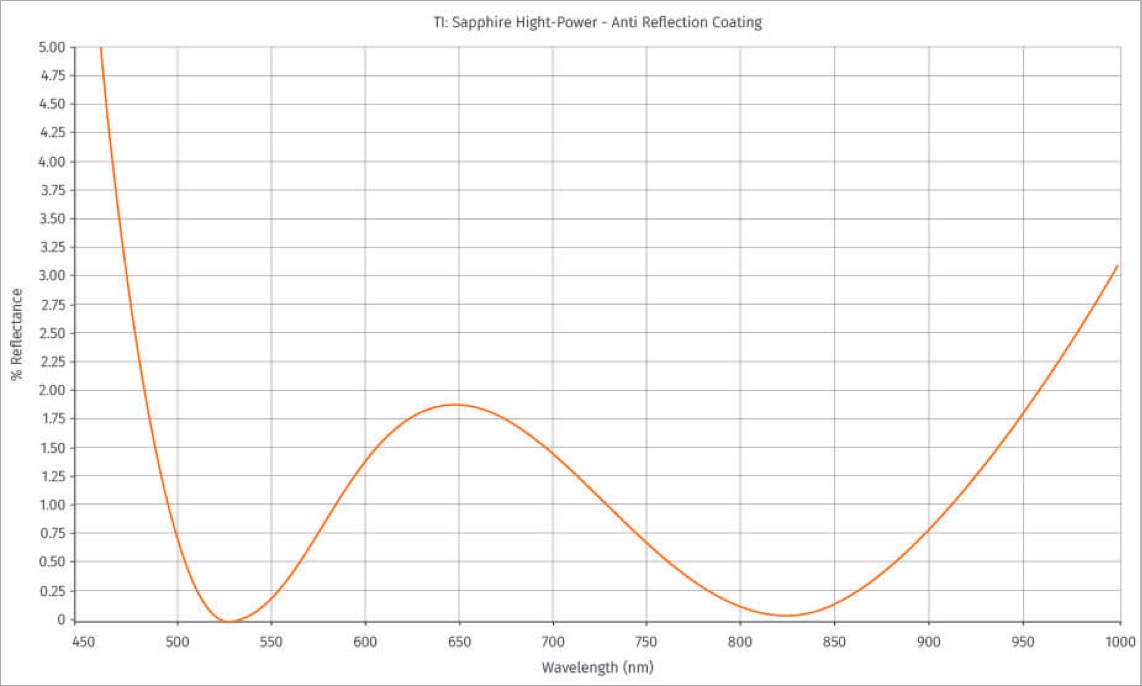

Anti-Reflection Coating

Crystal Systems offers advanced anti-reflection (AR) coatings for multipass amplifier crystals. Our coatings are engineered to provide maximum efficiency at the pump and lasing wavelengths. The AR coatings are successfully operating in the field with consistently high laser damage threshold results, allowing laser operators to calculate pump powers accurately, thereby maximizing power output with low risk of damage.

Laser Damage Threshold Testing of Ti:Sapphire AR Coating

The test results below come from one of the periodic tests that Crystal Systems performs on the AR coating designs used on HEM Ti:Sapphire amplifier crystals. These results are representative of the damage threshold that can be expected with our coatings.

Testing provided by Spica Technologies Inc.

Test Conditions

- Wavelength: 532nm

- Angle of Incidence: 0º (Normal)

- Pulse Repetition Frequencies: 10Hz

- Polarization: Linear

- Beam Profile: TEM Pulsewidth (FWHM): 10ns Axial Modes: Multiple Shots

- Pit Diameter: 570µm

- Number of Sites: 80

- Method: Laser Damage Frequency

- Exposure Duration: 200 shots/site

Test Sample

- Test Type: Laser Damage Threshold

- Substrate Material: HEM® Ti:Sapphire

- Sample Size: 1″Ø

- Coating Type: AR

Test Results

- Damage Definition: Plasma, increased He-Ne scattering, visible damage as observed using a 100X Nomarski Brightfield Microscope.

- Description of Results: Part Irradiated at 13.00 J/cm^2 With No Damage in 10 Sites

- Laser Damage Threshold: Calculated at 14.16 J/cm^2 Peak Fluence

Current Applications

HEM Ti:Sapphire’s wide emission range, (650nm to 1200nm), high-power density pumping capability along with excellent thermal properties enable today’s high-intensity laser platforms.

These facilities are creating the next generation of laser-based applications such as proton therapy, accelerator physics, nuclear physics, far-field physics, infrared spectroscopy and materials characterization. Crystal Systems works closely with its customers to develop new crystal designs so that the ultrafast femtoseconds laser community can continue to advance the reliability and performance of their products.

Request a Quote

Contact us for a quote on any of our sapphire products, or to discuss your specific technical application and requirements.

Request a quote